Machine Quilting 101

Here we go.

Let’s start with our equipment.

I started machine quilting about 20 years ago. I knew that I wanted to be able to quilt my projects and I knew that hand quilting wasn’t going to get it done. I hand quilted several large bed quilts and it took me forever. Besides my fingers got so cramped doing it.

The sewing machine that I had at that time was a great machine. But it only had a 7” opening between the needle and the side arm. I started out by quilting a “queen” size bed quilt. I don’t suggest you start that large, try something smaller first.

If you are serious about machine quilting your own large quilts I hope that you will invest in good equipment. Try out all the machines when you go to a bigger quilt show and see which one you like the best. They usually have deals at the shows and you can finance your purchase to spread out the payment without interest over a year.

The best advice I read and heard when I first started machine quilting was to make sure that the area where I was quilting was flush to the sewing bed of my machine. And I still believe that is the very best thing you can do to be more successful machine quilting a large quilt.

When I first started machine quilting I jerry rigged an arrangement to make that happen.

Here is a picture of what I had arranged.

I had a sewing table that my machine sat down in and I had two tables that were pushed up next to that table to make a larger sewing area to support my quilt while I was quilting it.

While this worked well for the space and time it is not ideal.

I now have a great sewing table from Mike at Tracey’s Tables. He delivers anywhere in the country. My sewing machine sits down in the table and I have drawers on two sides. I can also expand the area of the table where a large quilt will rest while I am quilting it.

I now have a newer model sewing machine that has a larger opening between the needle and the arm of the sewing machine. These two factors; a good machine with a larger opening from the needle to the arm and an area that is flush to the bed of your machine to support the weight of your quilt while you are quilting it, I think are the biggest contributors to success with machine quilting a large quilt, besides of course practice.

You should also invest in a good chair to sit in. I have an adjustable chair that allows me to raise and lower the height of the chair and also gives me good back and leg support. Because when you are quilting on a larger project you will spend lots of time sitting in this chair.

Those are your basic equipment issues. I worked long and hard to save up my money to buy these and feel that it was well worth the expense and am a happier quilter because of it.

NEEDLES AND THREAD

I was going to talk about basting a large quilt, but I think I will come back to that later.

One of the most important aspects of machine quilting on a domestic sewing machine,is what kind of thread are you going to use. And then depending on what kind of thread you use will determine what kind of needles that you will use.

There are all kinds of thread to use when you are machine quilting and the best advice is to try them out and see if you like them.

I personally like to use either rayon, cotton or silk thread, but there are many other choices. A good place to check out threads is at your local quilt store, or at a quilt show. There are always vendors who sell threads and you should try different kinds and see what kind of results you get with them.

A

A When I am using rayon thread I use an embroidery needle, it has a deep thread groove and larger eye for synthetic embroidery threads.

When I use silk thread I use a Sharp (Microtex) needle a very sharp point.

And when I use cotton thread I use a quilting needle, designed with special taper to the point for quilting through thick areas.

If I was to use Metalic thread I would use a Metafil needle it is a sharp point embroidery needle for synthetic threads.

If I used monofilament I would use either the Metafil or the Microtex.

Choosing the right tools for the right job is very important.

These are all sharp shank needles designed to pierce through multiple layers of fabric. You should not be using a universal needle, that is what you piece with. It is designed to separate the fibers in the fabric while you sew. And by the way sewing machine needles are designed to last only about 8 hours worth of sewing time and then they begin to wear and you should change them out.

When you dispose of your needles and used rotary blades I like to put them in a container rather then directly in the garbage.

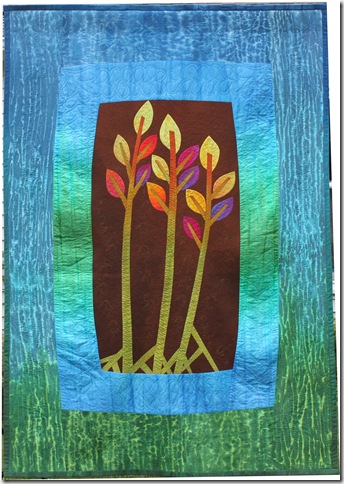

The thread used to go up the stem of these flowers is a 30 weight rayon thread.

The thread used to go up the stem of these flowers is a 30 weight rayon thread.Before I begin any quilting project I make a sample quilt sandwich out the fabric I will be quilting on with the same kind of batting and backing and do a test run with my threads and needles to make sure the tension is good on my machine and to also make sure that I like the thread I have picked out for the project.

This is a sample of just plain old stippleing. Warming up and checking my thread tension before I begin.

This is a sample of just plain old stippleing. Warming up and checking my thread tension before I begin.I like to use cotton in my bobbin. But again there are many choices you can have for bobbin thread. I use a lighter weight cotton in the bobbin than the thread that is on the top and I use the same color on top and bottom. You can also try using the same thread top and bottom if they are a thinner weight thread.

The weight of the thread is listed in numbers and they vary. 50 3ply mercerized cotton thread is good for construction of quilts and for quilting of medium weight cotton.

I like to use a 30 weight rayon thread. The smaller the number the thicker the thread. I use this for decorative stitching and to add a bolder statement to my quilting.

I also like to use silk thread it is usually a very thin thread and will recede into the background of your quilt.

Each thread type and style will give a different affect. You will need to experiment to find what you like to use.

A good resource for thread is the Superior Thread website. They have a wonderful resource page that tells you what needles to use with which of their threads.

And of course a great resource is Harriet Hargrave’s book on Heirloom Machine Quilting. I think it is now in it’s4th edition. I own a copy and refer to it all the time.

BASTING A LARGE QUILT

There are many ways to baste a quilt project together and over the years I have tried many of them. Lately what I like doing involves a spray adhesive.

For large bed quilts the method I use involves using three fold up modeled plastic tables to baste my quilt top on. You can get these at Walmart, Target, Home Depot, Menards, all kinds of places. They come in different dimensions and I have them in several different lengths and sizes. The three I use to baste the quilts on are 8’ long by 2’ wide I think. I can set up all three side by side in my living room and then fold them up again and store them in my garage and use for other things. Mostly for dyeing fabric outside in the summer.

First I like to iron out my pieced backing fabric on top of these tables. It is a large surface and big enough to hold the whole backing. I apply spray sizing to the backside of the backing; the right side of the fabric. This helps the back of the project move easily along the sewing surface when I am quilting it. I have had students tell me that they also use pledge on their sewing surfaces to help it be slicker. That is a technical term - slicker.

Once I have the backing ironed, I also iron my batting to get out all the wrinkles.

Once I have the backing ironed, I also iron my batting to get out all the wrinkles. I will then flip over the backing fabric and tape it to the tables.

I recommend you use packing tape or duct tape rather than masking tape. The masking tape will release when you don’t want it to. You

can also use big clips if you have them.

can also use big clips if you have them.I spray baste the backing fabric very lightly with spray adhesive 505. This is the product I have been using. It is great. I like it very much and use it now for all my quilting projects.

I spread out the batting and tap it down nice and smooth. I spray baste the top of the batting a little heavier than the backing. Just follow the directions on the can. When I lay down the quilt top I divide it into fourths so I can center it then open it up. It makes it easier to smooth out on the batting by unfolding it in sections because the batting with the spray adhesive is sticky, but not so sticky you can reposition the top.Be sure and put down newspaper or an old sheet to cover the floor underneath. You don’t want to get the adhesive spray on your carpet, floor or furniture.

Once the top is smoothed out I pin it around the outside just to hold it all together.

I roll it into a two tubes, and then roll up one end. You have to make it fit into your sewing machine space.

Depending on where you are working on the surface of the quilt you will be rerolling and rearranging as you go along.

QUILTING A LARGE QUILT

he first thing I do when I am quilting a large quilt is to anchor it somehow in a grid.

Many times there are lines to stitch in the ditch to anchor a quilt. Stitching in the ditch is stitching right next to the seam allowance in the ditch created when you press the seam in one direction. So it is important to make sure that you press seams in one direction. If you have seams that some how get crossed when stitched, you should go back and pick out the stitches and restitch the seam crossings.

When I stitch in the ditch I start in the center and work out to the edge. I use a walking foot on my machine and I adjust the tension of the top presser foot. Not all machines will let you adjust the tension but my Janome has a knob on the top left of the machine that loosens the presser foot tension.

I will rotate the quilt in quarter turns stitching in the ditch from the center out all the way around the quilt.

When I did this baby quilt that measures 35” x 50” I stitched in the ditch down each line between the seams to anchor the whole quilt. Once it was all anchored I went back and stippled the top of the quilt with yellow thread on the top and on the bottom. I didn’t know what the sex of this baby was that was receiving the quilt, so I picked a neutral yellow.

My Woods is a 70” x 90” quilt. The first thing I did was to stitch in the ditch down the long stems of the trees and then around the branches, and the outside of the brown. After that I quilted all the elements inside the brown area. Then I quilted the first border and stitched in the ditch around it and finally I quilted the outside border.